Welcome! Calling all Machine Owners

We want to connect with Machine Owners

Visit our new site for Troubleshooting

Electro Arc has Been Building the World’s Best Metal Disintegrators since 1947! Electro Arc celebrates 75 Years!

In 2019, Electro Arc, a customer of Stillion Industries since 1975 entered into negotiations with Stillion Industries for acquisition. Keith purchased the company, to pursue the opportunity to have a unique line of products. Electro Arc’s products consist of over 40 bespoke metal disintegrating machines and their accessories such as molybdenum electrodes, which are also produced onsite. Included with Electro Arc’s products, Ames Portable Hardness Testers which are now completely manufactured by Stillion Industries. Stillion Industries maintained all Electro Arc employees, doubling the number of employees.

Contact us at:

Email: sales@electroarc.com

Phone: 734-475-8527

Stillion Industries is located at:

2055 Lima Center Road

Dexter, MI 48130

We are open Monday – Friday from 7:00 AM – 3:00 PM

Recent Blog Post Blog Posts Blog Post

What KVA do I need?

If you are considering a metal disintegrator purchase, you have a lot of choices to make regarding which machine is best for your application. Electro Arc manufactures over 40 models of metal disintegrators. You will want to choose between a portable or tabletop model. Portable models are great for disintegrating on large parts. You can choose an AC or DC model. If you are choosing the AC option you will also need to decide what KVA you want your machine to be. Your KVA choice will determine how large a diameter you can disintegrate. Below is a guide to help you choose the correct KVA for your application:

As you can see, choosing your KVA has everything to do with the disintegration you are planning for. If you will only be disintegrating under 3/8″ taps and drills, a 3 KVA model will work out for you. One of our most popular portable models is the model 2-S which is available with the 3, 10, or 15 KVA option. The model 3-S is only available in the 3 KVA option. This model is ideal for infrequent use. If you are interested in our smallest tabletop, the 2-SE offers the same KVA options.

If you will need to disintegrate up to 5/8″ studs and bolts, you will want to go with the 10 KVA option for your AC metal disintegrator. The portable model 2-SQT offers you the option of 10, 15, or 20 KVA. The 2-SA series offers a larger tabletop size and the option of 10 or 15 KVA.

Power Supplies

3 KVA, 10 KVA, 15 KVA, 20 KVA

Larger-diameter holes require more power to maintain an effective arc.

3 KVA disintegrates taps up to 3/8″ in one single pass.

10 KVA disintegrates taps up to 3/4″ in one single pass.

15 KVA disintegrates taps up to 1-1/4″ in one single pass.

20 KVA designed for larger taps, drills, studs, and bolts.

Disintegrate up to 1 1/4″ taps and drills with a 15 KVA metal disintegrator.

Only choose the 20 KVA option if you will be disintegrating studs and bolts which are 1″ and larger.

Each machine is built to match your building power, you must specify 208, 240, 380, 480 or 550 at the time of order.

Choose a DC machine if you will be disintegrating carbide. The power input choices for a DC machine are 30 AMP 110-600. All Electro Arc metal disintegrators are single input voltage.

What KVA do I need?

If you are considering a metal disintegrator purchase, you have a lot of choices to make regarding which machine is best for your application. Electro Arc manufactures over 40 models of metal disintegrators. You will want to choose between a portable or tabletop model. Portable models are great for disintegrating on large parts. You can choose an AC or DC model. If you are choosing the AC option you will also need to decide what KVA you want your machine to be. Your KVA choice will determine how large a diameter you can disintegrate. Below is a guide to help you choose the correct KVA for your application:

As you can see, choosing your KVA has everything to do with the disintegration you are planning for. If you will only be disintegrating under 3/8″ taps and drills, a 3 KVA model will work out for you. One of our most popular portable models is the model 2-S which is available with the 3, 10, or 15 KVA option. The model 3-S is only available in the 3 KVA option. This model is ideal for infrequent use. If you are interested in our smallest tabletop, the 2-SE offers the same KVA options.

If you will need to disintegrate up to 5/8″ studs and bolts, you will want to go with the 10 KVA option for your AC metal disintegrator. The portable model 2-SQT offers you the option of 10, 15, or 20 KVA. The 2-SA series offers a larger tabletop size and the option of 10 or 15 KVA.

Power Supplies

3 KVA, 10 KVA, 15 KVA, 20 KVA

Larger-diameter holes require more power to maintain an effective arc.

3 KVA disintegrates taps up to 3/8″ in one single pass.

10 KVA disintegrates taps up to 3/4″ in one single pass.

15 KVA disintegrates taps up to 1-1/4″ in one single pass.

20 KVA designed for larger taps, drills, studs, and bolts.

Disintegrate up to 1 1/4″ taps and drills with a 15 KVA metal disintegrator.

Only choose the 20 KVA option if you will be disintegrating studs and bolts which are 1″ and larger.

Each machine is built to match your building power, you must specify 208, 240, 380, 480 or 550 at the time of order.

Choose a DC machine if you will be disintegrating carbide. The power input choices for a DC machine are 30 AMP 110-600. All Electro Arc metal disintegrators are single input voltage.

Ames Portable Hardness Testers

Learn More About Testing Thin Material With a Superficial Tetster:

Electro Arc purchased the Ames Portable Hardness Tester line in 1975. The Ames Precision Machine Works no longer exists as a separate company, the product line continues to be manufactured under the Electro Arc name. Stillion Industries purchased Electro Arc in 2019 and is now the parent company of both the Electro Arc and Ames product lines.

Stillion Industries continues to manufacture and calibrate Ames hardness testers. If you would like to purchase a new hardness tester, please visit the Ames website for more information. The Electro Arc website is dedicated to Electro Arc metal disintegrators. This article is designed to send you to the appropriate website for Ames testers. You can purchase Ames testers and accessories through the website, or you can contact Electro Arc to place an order. You can also send in your tester to be calibrated or repaired by our technician.

Here's a Look at the Capacity of Ames Testers:

The Ames product line consists of Standard and Superficial Hardness testers. All Ames hardness testers are machined by Stillion Industries in Dexter Michigan. We make 8 models of standard testers and 5 models of superficial testers, including the tube tester the model 1-ST. 98% of the components for Ames testers are made onsite at our facility. Every tester is hand-assembled and calibrated prior to sale. For this reason, there may be a delay when you order a new tester if we do not have that model hardness tester in stock.

Does Your Ames Tester Need Calibration?

Ames Portable Hardness Testers

Learn More About Testing Thin Material With a Superficial Tetster:

Electro Arc purchased the Ames Portable Hardness Tester line in 1975. The Ames Precision Machine Works no longer exists as a separate company, the product line continues to be manufactured under the Electro Arc name. Stillion Industries purchased Electro Arc in 2019 and is now the parent company of both the Electro Arc and Ames product lines.

Stillion Industries continues to manufacture and calibrate Ames hardness testers. If you would like to purchase a new hardness tester, please visit the Ames website for more information. The Electro Arc website is dedicated to Electro Arc metal disintegrators. This article is designed to send you to the appropriate website for Ames testers. You can purchase Ames testers and accessories through the website, or you can contact Electro Arc to place an order. You can also send in your tester to be calibrated or repaired by our technician.

Here's a Look at the Capacity of Ames Testers:

The Ames product line consists of Standard and Superficial Hardness testers. All Ames hardness testers are machined by Stillion Industries in Dexter Michigan. We make 8 models of standard testers and 5 models of superficial testers, including the tube tester the model 1-ST. 98% of the components for Ames testers are made onsite at our facility. Every tester is hand-assembled and calibrated prior to sale. For this reason, there may be a delay when you order a new tester if we do not have that model hardness tester in stock.

Does Your Ames Tester Need Calibration?

How to remove a broken carbide drill

Reference: Removing Carbide Tooling

There are two types of metal disintegrator power supplies. AC machines are built for speed and power. DC power supplies use a lower melting point and work better with carbide materials. Some of our DC-powered models include the 2-SC (portable) and the table model 2-SAC.

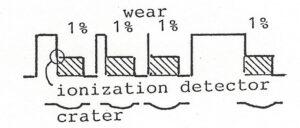

Removing carbide tooling with your Electro Arc DC metal disintegrator can be very easy if you follow these simple rules. The process for disintegrating carbide is very different than HSS high-speed steel because of the composition of carbide tooling. Increasing the heat or feed rate will only make the problem worse. With higher heat, the carbide will pool at the bottom of the hole and consume the electrode.

Disintegrating Carbide:

1) Use your “Heat Selector Chart” to select the appropriate electrode size and heat selection.

2) Ensure the part is well grounded.

3) Good coolant flow is critical. 90 psi @120gpm.

4) Use your Current monitoring LEDs’ for the feed.

5) LED’s should never exceed the second Green LED. Any faster will stall the process and consume electrode.

Suggested Electrodes for downhole drill heads with carbide bits

Removing carbide bit(s) from drill heads can be made easy. There are many ways to remove the buttons but only one safe way. Using a torch and pounding on the drill hears can damage the structure and the temper of the material. Disintegrators do neither.

There are two types of metal disintegrator power supplies. AC machines are built for speed and power. DC power supplies use a lower melting point and work better with the carbide materials. You will want to use one of our DC-powered models for a job like this 2-SC (portable) and the table model 2-SAC.

Typically, a hex graphite electrode is used. The electrode is sized to disintegrate near enough to leave a thin shell behind. See the time studies below for a better idea of how long your disintegration job will take. After disintegration, the operator would be able to remove the shell with a hammer and punch. If done correctly, there would be no damage to the hole or thermal distortion to the bit.

When you remove carbide bits from drill heads, the following graphite electrodes are recommended:

To remove a carbide bit:

Save the bit:

Disintegrate the hole using the suggested electrode size. With a hammer and punch, crack the bit shell and remove the remnants to clear the hole.

To save the bit, disintegrate a hole with an inside diameter large enough to leave a thin shell around the bit. Use a hammer and punch to crack the shell and remove the carbide bit.

How to remove a broken carbide drill

Reference: Removing Carbide Tooling

There are two types of metal disintegrator power supplies. AC machines are built for speed and power. DC power supplies use a lower melting point and work better with carbide materials. Some of our DC-powered models include the 2-SC (portable) and the table model 2-SAC.

Removing carbide tooling with your Electro Arc DC metal disintegrator can be very easy if you follow these simple rules. The process for disintegrating carbide is very different than HSS high-speed steel because of the composition of carbide tooling. Increasing the heat or feed rate will only make the problem worse. With higher heat, the carbide will pool at the bottom of the hole and consume the electrode.

Disintegrating Carbide:

1) Use your “Heat Selector Chart” to select the appropriate electrode size and heat selection.

2) Ensure the part is well grounded.

3) Good coolant flow is critical. 90 psi @120gpm.

4) Use your Current monitoring LEDs’ for the feed.

5) LED’s should never exceed the second Green LED. Any faster will stall the process and consume electrode.

Suggested Electrodes for downhole drill heads with carbide bits

Removing carbide bit(s) from drill heads can be made easy. There are many ways to remove the buttons but only one safe way. Using a torch and pounding on the drill hears can damage the structure and the temper of the material. Disintegrators do neither.

There are two types of metal disintegrator power supplies. AC machines are built for speed and power. DC power supplies use a lower melting point and work better with the carbide materials. You will want to use one of our DC-powered models for a job like this 2-SC (portable) and the table model 2-SAC.

Typically, a hex graphite electrode is used. The electrode is sized to disintegrate near enough to leave a thin shell behind. See the time studies below for a better idea of how long your disintegration job will take. After disintegration, the operator would be able to remove the shell with a hammer and punch. If done correctly, there would be no damage to the hole or thermal distortion to the bit.

When you remove carbide bits from drill heads, the following graphite electrodes are recommended:

To remove a carbide bit:

Save the bit:

Disintegrate the hole using the suggested electrode size. With a hammer and punch, crack the bit shell and remove the remnants to clear the hole.

To save the bit, disintegrate a hole with an inside diameter large enough to leave a thin shell around the bit. Use a hammer and punch to crack the shell and remove the carbide bit.